Corrosion Protection

Smart Particles enhance the corrosion protection performance of existing coating systems substantially.

In testing at NASA Kennedy Space Center’s Beachside Atmospheric Corrosion Test Site, Smart Particles dramatically increased the performance of commercial and MIL-Spec coatings.

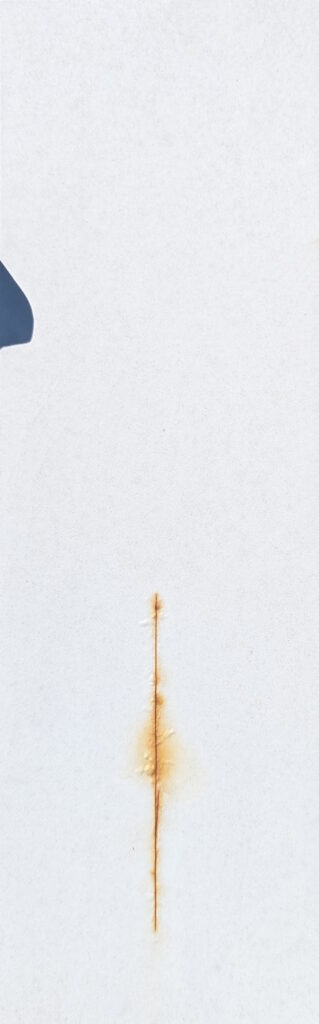

Commercial DTM Alkyd

Two coats of commercial DTM Alkyd on carbon steel: Atmospheric Exposure testing at NASA KSC Beachside Exposure Test Site. Primer layer contains no Smart Particles (Control) or 5% Smart Particles

No Smart Particles

1 Year

2 Years

2.5 Years

With 5% Smart Particles

1 Year

2 Years

2.5 Years

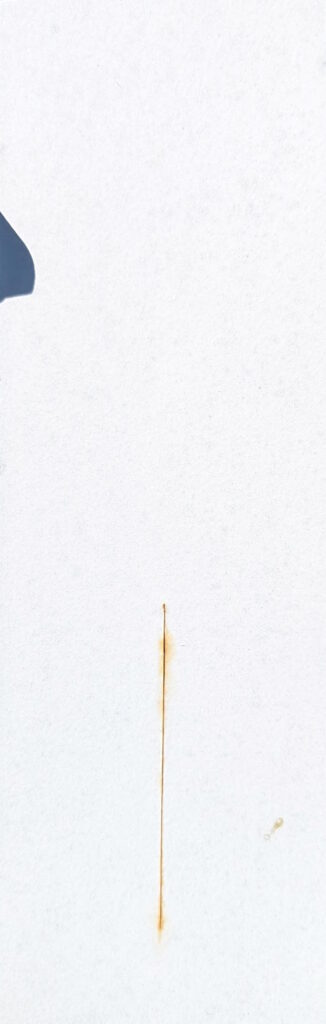

Navy MIL-Spec Coating

Two coats of MIL-DTL-24441 epoxy-polyamide coatings on carbon steel: Atmospheric Exposure testing at NASA KSC Beachside Exposure Test Site. Primer layer contains no Smart Particles (Control) or 5% Smart Particles

No Smart Particles

1 Year

1.5 Years

With 5% Smart Particles

1 Year

1.5 Years

Coating Formulation

Smart Particles are powders that consist of microparticles.

Smart Particles are powders that are formulated into many coating types:

- Solventborne

- Waterborne

- Powder

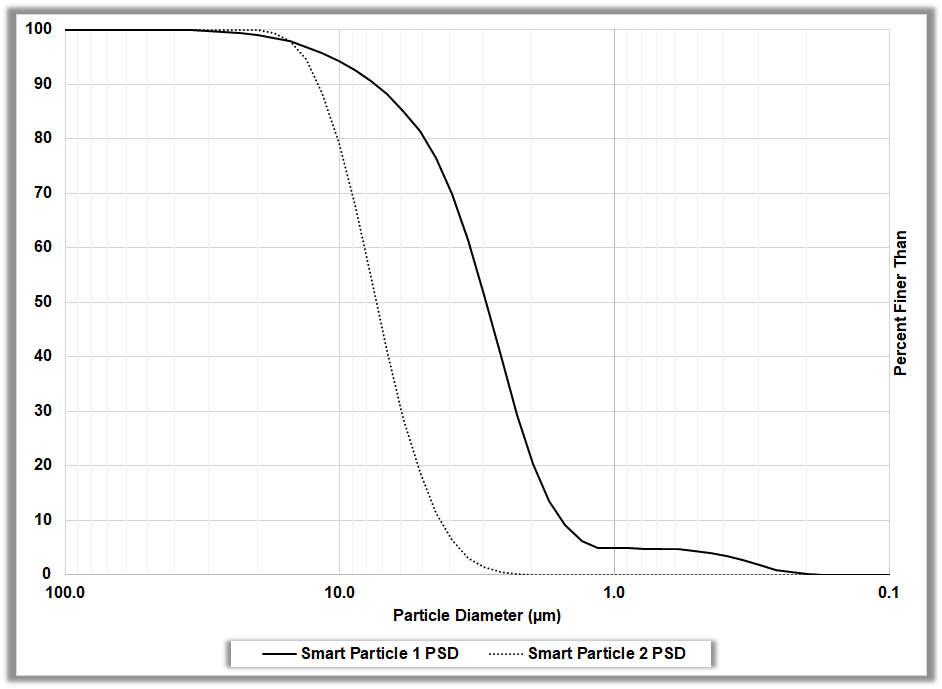

Particle Size Distribution

Smart Particles are fine powders that are formulated into coatings with ease with little coating reformulation, using industry methods. Smart Particles can be added during the grind, the let-down or as a post-addition.

On-Demand Release

Smart Particles are porous silica microparticles with corrosion inhibitors stabilized within the pores. Formulated into coatings, they remain inert until the onset of corrosion itself triggers the release of the corrosion inhibitors. As such, Smart Particles deliver corrosion inhibitors on-demand – the right amount at the right time in the right place.